Audi Electric biturbo

Audi is taking another big step forward with the electric biturbo. In this future technology, a secondary compressor boosts the main turbocharger at lower engine speeds.

Nearly a quarter century ago, Audi provided a decisive impetus to international diesel engineering – in 1989, the first diesel with direct fuel injection, turbocharging and electronic control made its debut in the Audi 100. Since then, the TDI has enjoyed remarkable success.

Turbocharging makes a lot of sense especially in combination with diesel engines. It enhances performance and substantially reduces fuel consumption and emissions – this represents downsizing par excellence compared with naturally aspirated engines. Referenced to their displacement, TDI engines have realized power gains of over 100 percent and torque gains of 70 percent since 1989. Over the same time period, emissions have been reduced by 95 percent.

The latest development stage from Audi is a biturbo version of the 3.0 TDI – it has a power output of 230 kW (313 hp) and a maximum torque of 650 Nm (479.42 lb-ft) between 1,450 and 2,800 rpm. Its specific power output is 77.5 kW (105.5 hp) per liter displacement. However, its combined fuel consumption in the A6 is only 6.4 liters of fuel per 100 km (36.75 US mpg), equivalent to CO2 emissions of 169 grams per km (271.98 g/mile).

What all turbocharged engines have in common is that the turbocharger is driven by energy from the exhaust. This means that starting from very low revs, the rise in boost pressure and therefore torque becomes gradually greater only as the exhaust energy increases.

A new development stage is the electric biturbo. This makes it possible – independently of the exhaust energy available – to build up charge pressure quickly and achieve high levels of torque even at very low revs.

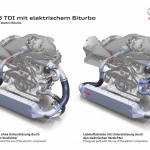

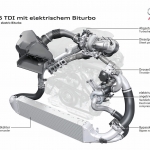

In advanced diesel development at Audi’s site in Neckarsulm, a 3.0 V6 TDI was built and calibrated with an electric biturbo. It is a combination of a conventional gas-driven turbocharger with a secondary electrically driven compressor – whose exterior appearance is almost identical to that of a conventional turbocharger.

Instead of a turbine wheel driven by the exhaust gas stream, this is an auxiliary charging stage arranged in line with the gas-driven turbocharger. It integrates a small electric motor that can accelerate its turbine to very high speeds in an extremely short time. The electrically driven compressor is placed after the main turbocharger and intercooler in the charge air path. In most operating states, the charge air is routed around it via a bypass. However, when the flap integrated in the bypass closes – i.e. when the main turbocharger’s energy output is low – the air is directed into the electric compressor and is compressed there a second time.

The results of the new concept are impressive. Torque buildup occurs significantly earlier in every drive-off, which the driver perceives as a distinct boost in performance.

The energy required to drive the electric compressor is largely offset by battery regeneration during coasting phases, so that the end effect is essentially neutral with regard to energy consumption.

The flexible and compact charge air path enables two-stage turbocharging with just one turbine that is driven by exhaust gas. The reduced heat demand enables earlier activation of the catalytic converter.